Featured In

NY Fashion Week Online

How to Buy a $3 Million Panama Hat

June 6, 2015

By Pablo Avion

Meet Brent Black, the Man Who’s Saving Panama Hats … and Helping People

New York Fashion Week: Men’s,

Fashion Week Online is continuing our exploration of bespoke and handmade menswear. Which

brings us to Brent Black. Brent Black is trying to save Ecuador’s most famous art form, the

incongruously named “Panama” hat. The funny part is, he seems to be succeeding.

New York Fashion Week: Men’s,

Fashion Week Online is continuing our exploration of bespoke and handmade menswear. Which

brings us to Brent Black. Brent Black is trying to save Ecuador’s most famous art form, the

incongruously named “Panama” hat. The funny part is, he seems to be succeeding.

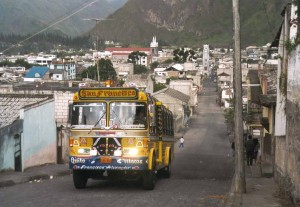

The finest “Panamas” are made in Montecristi, an unassuming little town in western Ecuador. It was this coast that created one of the world’s most famous icons, the “Panama,” worn by everyone from Napoleon to Mark Twain to JFK to Pierce Brosnan to … well, Charlie Sheen.

Their death has long been predicted. The process of creating one is ridiculous long and involved, so much so that the labor is split between no less than 7 craftspeople: weaver, backweaver, tightener, cutter, bleacher, ironer, and finally the “blocker” (the person who shapes the hat).

That’s really the tip of the iceberg; if you want to know more, you can check this out.

WARNING: Prepare to have your mind blown.

As with most things, machines now dominate the picture, which means lower prices, and — not surprisingly — lower quality. But it goes beyond questions of price. The question is how to save an art form, while simultaneously helping the artists themselves make the living they deserve.

Enter Brent Black, an obsessive who’s created a foundation to achieve dual objectives: save the Ecuadorian hat, and help a community profit from their expertise.

Q: What about Montecristi hats has essentially led you to dedicate your life to their preservation?

As I said in Objects of Desire (by Patrice Farameh), I wanted

to give CPR to an art form on the edge of death, to an art that is the cultural heritage — not

only of Ecuador — but the whole world.

As I said in Objects of Desire (by Patrice Farameh), I wanted

to give CPR to an art form on the edge of death, to an art that is the cultural heritage — not

only of Ecuador — but the whole world.

Montecristi hats are a global fashion icon. For

more than two hundred years, Montecristi hats have been worn by kings, emperors, princes, presidents,

prime ministers, movie stars, tycoons, and those who want to look like them. Napoleon wore a Montecristi

hat. Mark Twain wore a Montecristi hat. Churchill, FDR, JFK wore Montecristi hats. I couldn’t just stand

by and let the art die.

Two years before I touched my first Montecristi hat, the extinction of the art had been predicted to occur in less than twenty years (Tom Miller, The Panama Hat Trail). I accepted Tom’s prediction as a challenge. Twenty-five years after that prediction, the art is still alive. With my sponsorship, finer hats are being woven now than were being woven twenty-three years ago. During those twenty-three years, I have bought more Montecristi hats than anyone in the world. Probably sold more, too.

Q: How did the bug “bite” you, so to speak? What specifically about this art form was able to draw you away from a lucrative career at one of the world’s top advertising agencies?

I worked in advertising from 1972 until 2001, in Philadelphia, Cincinnati, Chicago, Dallas, and San Francisco, all of which were too cold. I moved to Hawaii in 1987, and stayed here.

In 1988, while Executive Creative Director of Ogilvy & Mather Honolulu, I traveled solo to Montecristi on an “adventure” vacation. I had read the book The Panama Hat Trail and thought it would be interesting to go see the hats I had read about. I had never seen or felt a Montecristi hat.

I spoke maybe 20 words of Spanish. No one in Montecristi spoke any English. So it was, in fact, an adventure.

The book I read had mentioned Rosendo Delgado as the largest hat dealer in Montecristi, so I found his house and asked to see some hats.

$25,000 Fedora, sold to Charlie Sheen

When I touched my first Montecristi hat, it touched me back. I had not expected to have such a visceral response to a hat. Instantly, I understood why, for two centuries, Montecristi hats had been so highly prized by kings, emperors, and anyone else who could find them and afford them.

Sr. Delgado and others told me that each year there were fewer weavers and fewer hats. The art was dying.

I reasoned that if weavers were weaving fewer hats, it must be because buyers were buying fewer hats. Simple economics: if people show up with stacks of money, other people will show up with stacks of hats. In order to increase supply, increase demand. Perhaps my years of marketing experience might enable me to increase the market for Montecristi hats, which would increase demand and, in theory, supply.

Tom Miller, author of The Panama Hat Trail, also had reported that the art was dying. He predicted it would be extinct within 20 years. I decided that I would do my best to make sure that his prediction would not come true. Twenty-three years later, the art is, in many ways, healthier than it was in 1988. It seems likely that the prediction itself was a major factor in causing the prediction not to come true.

During my week in Montecristi, I bought as many hats as I could afford and took them back to Honolulu. No clue what I would actually do with the unblocked hat bodies to turn them into marketable hats, nor how I would sell them. I did not quit my day job.

By coincidence, one of the top executives of O&M Honolulu had left the agency to launch a men’s tropical clothing retail business, with shops in some of the resort hotels here in Hawaii. I handed him one of those very first hats I brought back from Montecristi. It was unblocked, no style, no ribbon, just a hat body. He also fell in love with Montecristi hats and was on fire to offer them in his shops. A lucky break for my would-be hat business – a client.

The hat business was created in order to try to save the art, not to try to make money. I have had some success in trying to save the art, and great success in not making money.

There was nothing in my background to explain why I had become so focused on, so obsessed with, Montecristi hats. I had earned my bachelor’s degree from Johns Hopkins University, believing I was on my way to becoming a cardio-vascular surgeon. Obviously, I changed my career plans. I enjoyed my 29 years as an advertising writer, creative director, producer, director, photographer, designer, etc., but had no clue I was training to become a hatter who would attempt to preserve an endangered art form in Ecuador.

I have but one explanation – the hats chose me.

Q: Name some ways that the art form / manufacturing process has degraded at some of the top Panama hat manufacturers to allow for a cheaper, mass-produced product?

Borsalino offers some factory made Montecristi hats that retail for about $1300. The hats themselves are comparable to my $700 hats. The blocking and finishing of my hats is far superior. Borsalino uses a grosgrain ribbon as a sweatband. In a $1300 hat!? Personally, I think that’s outrageous. I also custom size my hats. Borsalino’s pricing is correct as a business model. My prices are much too low.

There are only a couple of other hatters in the US whose blocking and finishing I respect and consider to be comparable in quality to my own. Both charge much higher prices than I. No doubt they are smarter.

One of the most common “tricks” in the global market place is for retailers to sell hats represented to be Montecristi hats, which are not Montecristi hats. Sadly, misrepresenting Cuenca hats to be Montecristi hats is not at all unusual. Retail shoppers simply do not know the difference and trust the retailers to tell the truth.

This practice of misrepresenting Cuenca hats to be Montecristi hats is, in my judgment, the single greatest factor accounting for the near extinction of Montecristi hats. It is not unusual for exporters in Cuenca to misrepresent Cuenca hats to be Montecristi hats.

The current total annual production of Montecristi hats is estimated to be about 2000 hats.

Q: Tell us about the $3 million dollar hat. Why is the finest Montecristi ever created, and who

created it?

Q: Tell us about the $3 million dollar hat. Why is the finest Montecristi ever created, and who

created it?

The Hat is the most finely woven Montecristi hat ever

created.

Finer than Napoleon’s Montecristi. Finer than Edward VII’s, Winston Churchill’s,

Emperor Akihito’s, George V’s, Humphrey Bogart’s, JFK’s, Schwarzenegger’s, Stallone’s, Francis Ford

Coppola’s … finer than any Montecristi ever worn by anyone.

The weaver of The Hat is Simón Espinal, the best weaver alive, possibly the best who ever lived. He began weaving it on June 19, 2013, after three weeks of preparing the straw, and finished the hat on February 20, 2014. 8 months to weave one hat.

The Hat is the highest expression of the art of Montecristi, the finest-ever example of an art legendary for fineness.

The price of The Hat is $3 million, and it’s priced as art, not apparel. Proceeds will be used to save the art.

A full hat production center will be built in Montecristi, including commercial greenhouses to grow the plants in perfect micro-climates, facilities for straw preparation, traditional artisan finishing of hats, complete blocking and finishing of hats by hand and by state-of-the-art hat presses, plus a multi-media visitor center to celebrate and showcase the art.

Q: The weave count of The Hat, as shown in Sorcerer of Straw, is 63 x 62. What’s a typical count?

The fineness of a Montecristi hat is measured by counting the rows of weave per inch, first horizontally then vertically.

Weave count for a commercial Montecristi fino might be 20 x 20 = 400. A hat with a weave count above 1000 is rare. Simón Espinal normally weaves 2 hats each year. Weave counts are about 2500.

The weave count of The Hat is 63 x 62 = 3906.

So The Hat has a weave count approximately 10 times greater than a commercial Montecristo fino.

Q: What does a typical workday look like for you?

At present, my time must

be split among blocking [shaping] hats, shipping hats, taking orders, keeping up with email, accounting,

and all the various aspects of marketing (such as answering interview questions and researching

photographs). I have no employees. I do everything myself. I wrote my website myself. I did most of the

photos myself, and much of the design. Even the ads for my hats are written, photographed, and art

directed by me.

At present, my time must

be split among blocking [shaping] hats, shipping hats, taking orders, keeping up with email, accounting,

and all the various aspects of marketing (such as answering interview questions and researching

photographs). I have no employees. I do everything myself. I wrote my website myself. I did most of the

photos myself, and much of the design. Even the ads for my hats are written, photographed, and art

directed by me.

Pretty crazy workload. During the busy summer season, between April and

October, it nearly kills me to try to keep up with everything. I generally work seven days per week,

usually 10 to 14 hours per day.

10 hours in a day is about my limit for blocking. It’s too demanding physically to go longer. I probably average 35 to 40 hours per week during the busy season. Maybe another 20 to 30 hours per week doing other business things. By August, I can become rather cranky and curmudgeonly.

One of the things I hate most is clients who call and email to ask how their hats are coming. I have 40 or 50 hats in the «system» at any given time. If all of those clients call or email once a week to check on their hats, and if I can take care of each inquiry in only 15 minutes, then I’m spending 10 to 12 hours per week giving status reports. I am happy that my clients are eager to have their hats, but their hats will ship sooner if they are quietly patient.

My favorite clients are the ones who say, “No hurry. Take as much time as you need to get it right. I am looking forward to wearing a beautiful work of art.”

Many clients seem to think “custom made” means I take a finished manufactured hat off a shelf just for them. No, I actually have to block, style, and finish each hat by hand. We live in a world of mass-produced products, and in an age of expected instant gratification. Most clients have no comprehension of what I do. On some days, I have no comprehension of why I do it.

Q: Why do you do it?

I do it so others can share the wonder and joy I experienced when I saw and held my first Montecristi hat. The three most frequent comments I get from clients after they receive their first Montecristi hat are: 1. I love it! 2. It is even better than I expected! 3. It weighs almost nothing! Probably number 4 would be: I want another one!

Consumer warning: My hats can be quite addictive.

My workroom is in my home. In fact, 85% of the square footage of my home is used for the hats. My carport is stacked floor to ceiling with shipping boxes. There is still enough room for my car, but just barely.

Q: What differentiates a quality Montecristi Panama hat and a poorly made one (at a possibly higher price point)?

Easy. Relentless obsession with details. Unflinching refusal to compromise quality in any way. Stubborn persistence to do something over and over and over until it comes out right.

I can say for myself, it’s not good enough to get 99 out of 100 hats absolutely right. What about the client who gets the 100th hat? S/he doesn’t care that my previous 99 creations were perfect. S/he only has that one hat, which must also be perfect. I block and style the hats myself. I put my name in them. My name is my brand, and my name is my bond.

Q: Tell us about the Montecristi Foundation. Why is it so important?

The purpose of my company, the reason it was created in the first place, is to keep alive the art of fine hat weaving in Montecristi. To save an art, one must save the artists. My company was beginning to fund medical care, food for weavers, eyeglasses, and other projects of a charitable nature, “good works.” I was advised that setting up a non-profit foundation would allow the business activities to be clearly separated from the charitable activities.

The Montecristi Foundation, Inc. is a not-for-profit private operating foundation.

For several years, we focused on providing free medical care to the village of Pile. Then, finally, the

government discovered the village and began a regular program of medical care, so we redirected our

resources to free eye exams, free eyeglasses, free supplies to weavers, free safety masks to protect

weavers from sulfur fumes when bleaching the straw, and so on. The foundation, along with Hartford York

hat catalogue, funded an important water project for the village. The foundation established a weaving

school in Pile where the next generation is learning to weave the very finest Montecristi hats, learning

to keep the legend alive.

The Montecristi Foundation, Inc. is a not-for-profit private operating foundation.

For several years, we focused on providing free medical care to the village of Pile. Then, finally, the

government discovered the village and began a regular program of medical care, so we redirected our

resources to free eye exams, free eyeglasses, free supplies to weavers, free safety masks to protect

weavers from sulfur fumes when bleaching the straw, and so on. The foundation, along with Hartford York

hat catalogue, funded an important water project for the village. The foundation established a weaving

school in Pile where the next generation is learning to weave the very finest Montecristi hats, learning

to keep the legend alive.

The foundation helped to fund the cost of the legal action to apply, successfully, for the Denomination of Origin for Montecrisiti hats. Most of the effort was pro bono by Paz Horowitz law firm in Quito. The foundation has designed an environmentally safe, worker-safe “oven” for bleaching the hats with sulfur.

I think that’s all good stuff. Stuff worth doing. The foundation helps me do it. I wish we could do more.

Q: Just for fun, name five celebrity clients. Or / and tell us a fun story.

When my hats were sold by Davidoff (cigars) in their Rodeo Drive store, Charlie Sheen bought one as a Father’s Day present for Martin Sheen, and later bought another 11 hats as “wrap party” (completion of filming of a movie) gifts. In 2008, he contacted me by email and purchased a $25,000 Classic Fedora. Huge commissions were paid to the weaver and other artisans who created the hat. Additional funds were used to build a water project for the village. So, despite his public persona and his adventures with the media, Charlie Sheen is, to me, a patron of the art of Montecristi and a do-gooder of the first order.

Most of my celebrity clients bought their hats in resort shops in Hawaii when I sold my hats wholesale. Pierce Brosnan bought a hat in a resort on Maui and subsequently called me directly to buy a second hat. He is an extraordinarily nice man. I was speaking with him by phone one day while he was in his condo on Kauai. He had to go answer the door or take another call or something and gave the phone over to his wife while she was cooking breakfast. Also an extremely nice person. At one point, she had to put the phone down because the eggs were burning. I could hear children in the room. I enjoyed being included in their domestic life for those few moments. I will always love them for that. They were nice people, just being nice people.

Text and photos © 1988-2022, B. Brent Black. All rights reserved.

100% Secure Shopping